How to Prevent Shotgun Choke Malfunctions

30th Jul 2014

Just as rifle and handgun shooters often tune their firearms to achieve the best possible performance, shotgun users also can enhance the shooting qualities of their guns. Shotgun modifications or tuning can involve a variety of different aspects, including the stock design and fit, sights, trigger function, and choke.

Shotgun choke is perhaps the one area where a lack of knowledge or improper maintenance can actually lead to serious damage to the gun and possible injury to the shooter or bystanders. While many things associated with firearms have improved with time and developing technologies, there are perhaps more incidents or problems with chokes now than ever before.

For the most part, up until the early 1970s, most American shotgunners used guns in which the barrel or barrels had fixed, nonadjustable chokes. The choke was simply a portion of the barrel at the muzzle that was of slightly smaller diameter than the rest of the bore. This smaller diameter section created a degree of constriction, which, in turn, helped concentrate the shot as it left the barrel. Generally, the greater the degree of constriction, the greater the degree of concentration of the shot and the denser the shot pattern on the target.

Because this choke was built into the barrel, shooters were not able to change or modify it. They could have a gunsmith open up the degree of constriction, but that took time and specialized equipment. It definitely wasn’t something you could do in the field. On the other hand, if you wanted more constriction or a tighter choke, you were pretty much out of luck and simply had to buy another barrel if your gun was a takedown model or another gun if you had a fixed barrel. It was not the ideal situation.

All that changed in 1969 when Winchester introduced the Winchoke screw-in choke tube system. It was an immense success. One way to judge just how successful it was is to look at how many other gun companies quickly jumped on board the bandwagon and began to offer their shotguns with screw-in choke tubes. Just about everybody did it! A shooter could easily change the degree of choke, or constriction, in his barrel while in the field. If he started out with a Modified choke but found the shots were longer and required a denser pattern, he could quickly and easily turn out the Modified tube and screw in a Full or Extra Full tube. Nothing could be easier and more helpful to the shooter. It also made it possible for the gun owner to use his favorite (or only) shotgun for a variety of different types of hunting or shooting games. You could use the shotgun for shooting skeet or trap and then use the same gun for hunting quail or turkey or pass shooting at geese by just changing the choke tube.

Common Problems with Screw-In Chokes

However, all was not sweetness and light. There were—and still are—problems, but these tend to be caused more by operator error than the design of the screw-in choke tubes. Any busy gunsmith who works with a lot of shotguns sees a number of guns with blown-out choke tubes, split or bulged muzzles, and tubes stuck in the barrel. Most of these incidents are caused by improper use of the choke tube and can be avoided.

Usually, when choke tubes stick in a barrel and cannot be removed, it’s caused by a failure to clean and lubricate the threads in the barrel and on the choke tube body. No matter what type of tube you use, the threads tend to be very fine and easily become packed with carbon and fouling. The threads must be cleaned regularly and lubricated. There are a number of good choke tube lubricants on the market, and all that I’ve used work well.

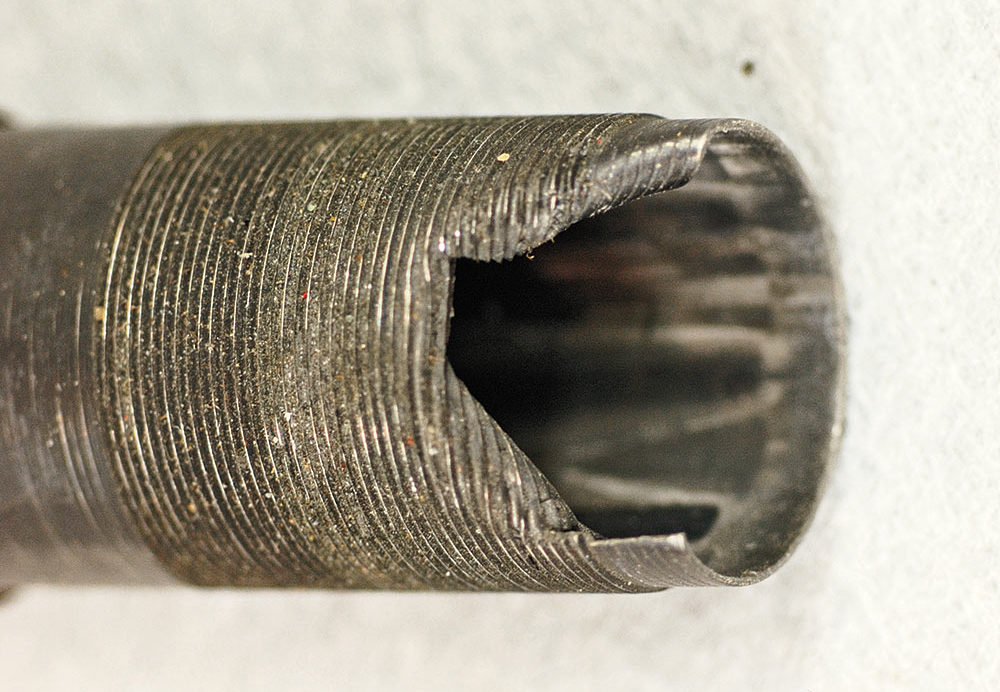

The skirt, or breech end, of the tube must seat firmly and evenly on a small corresponding shelf inside the barrel. If there’s a gap between the skirt and this shelf, you’ll have fouling forced between the tube and the inside of the barrel. This will gum up the threads and possibly cause the tube to stick in the barrel. At worst, it can cause a portion of the tube skirt to be lifted as fouling and shot cup or wad plastic builds up under the skirt. This can eventually reach a point where the following shot hits the underside of the skirt and blows the tube out the barrel, bulges the end of the barrel, or even splits the end of the barrel. It can be a major disaster.

This can be avoided by simply making sure the tube fits the barrel and seats firmly and evenly on the internal shelf. You can actually check this by running a small piece of wire, bent at a 90-degree angle, over the junction of the end of the choke tube skirt and the internal shelf of the barrel. If there’s a gap, you’ll feel it.

One of the other major causes of damage to shotguns with screw-in choke tubes is caused by the use of damaged tubes. The typical modern screw-in choke tube is very, very thin. It has to be! Most shotgun barrels are also thin to avoid excessive weight. The choke tube has to be even thinner, and, consequently, it is more fragile. If dropped on a hard surface, most choke tubes can bend in the super-thin area of the skirt.

When the tube skirt is bent, it will almost always bend inward, which might not be noticed. The problem is that this bend might well project above the lip of the internal choke tube shelf in the barrel. Again, when the shot is fired, the lead shot or shot cup can catch the bend and tear out the tube. The only way to avoid this problem is to be extra careful with your tubes. If and when you drop one, examine it carefully and pay special attention to the skirt. If there is even the smallest bend, do not even think of using that tube until it has been repaired or, better yet, replaced.

Until next time, good luck and good gunsmithing!